China Good Quality Large Capacity Proof Load Water Bags for Crane Load Weight Testing

Description

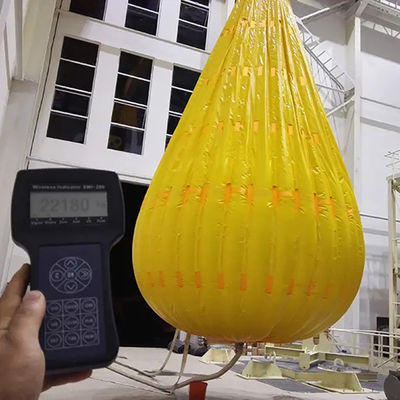

Load testing water bags are specialized testing equipment that are used to simulate the weight and load conditions experienced by various structures, such as cranes, bridges, and platforms. These bags are filled with water and exert weight that closely resembles the anticipated load to ensure the structural integrity and safety of the tested structure.

The load testing water bags are made of high-strength materials that are reinforced to withstand the weight of the water and prevent any leakage. They are designed to be portable and easily transportable, allowing them to be set up in different locations for different applications.

Water bags are available in various sizes and capacities, ranging from a few hundred kilograms to several tonnes, depending on the load requirements of the specific testing project. They can be easily filled and emptied, making them a convenient and efficient solution for load testing.

Load testing water bags are widely used in industries such as construction, maritime, and offshore operations. They provide a safe and cost-effective method for load testing, as they eliminate the need for additional heavy equipment or permanent structures. They can be used for both static and dynamic load testing, ensuring that the structure can withstand various load conditions.

Overall, load testing water bags are essential tools for assessing the structural integrity of different types of structures. They provide accurate load simulation and offer a safe and reliable solution for load testing, ensuring the safety and durability of the tested structure.

Specifications

| Application |

Proof Load Testing, Offshore Load Testing, Structural Load Testing, Ship Load Testing, Industrial Equipment Testing, Research and Development. |

| Content |

100% POLYVINYL CHLORIDE |

| PHTHALATE |

7P Phthalate Free (includes all Phthalates listed in CAL Prop 65, CPSIA and REACH) |

| Backing Material Size |

1.8/2.0 MM X 1.55M, thickness produced as per your request. |

| Weight |

37.1 oz square yard/ 1450 +- 50 GSM |

| Special |

UV Resistant |

| 7P Phthalate Free (includes all Phthalates listed in CAL Prop 65, CPSIA and REACH) |

| BPA Free / Tris Free / Formaldehyde Free |

| Does not contain Conflict Minerals |

| CARE INSTRUCTIONS |

Rinse with fresh water and air dry |

| Do not store with seawater and keep away from heat sources |

| Available sizes |

5000 kg |

| 8,000 kg |

| 1,0000 kg |

| 15,000 kg |

| 20,000 kg |

| 30,000 kg |

| 50,000 kg |

| 100,000 kg |

| Special sizes could be customized |

| Logo |

Supported |

| MODEL |

Weight |

Volume |

Empty Height (Length) |

Filled

Height (Length)

|

Max

Diam

(ø)

|

Dry Weight without accessories |

| kg |

Liters / m3 |

m |

m |

m |

kg |

| lbs |

USG |

ft |

ft |

ft |

lbs |

| HM-1T |

1,000 |

1,000 / 1 |

2.52 |

2.23 |

1.39 |

36 |

| 2,204 |

264 |

8.27 |

7.33 |

4.56 |

80 |

| HM-2T |

2,000 |

2,000 / 2 |

2.87 |

2.6 |

1.65 |

41 |

| 4,409 |

528 |

9.41 |

8.5 |

5.43 |

90 |

| HM-3T |

3,000 |

3,000 / 3 |

3.38 |

2.97 |

1.82 |

50 |

| 6,613 |

792 |

11.11 |

9.75 |

6.0 |

110 |

| HM-4T |

4,000 |

4,000 / 4 |

3.41 |

3.07 |

1.88 |

64 |

| 8,818 |

1,056 |

11.22 |

10.1 |

6.16 |

141 |

| HM-5T |

5,000 |

5,000 / 5 |

4.14 |

3.52 |

2.13 |

80 |

| 11,023 |

1,320 |

13.60 |

11.58 |

7.0 |

176 |

| HM-6T |

6,000 |

6,000 / 6 |

4.39 |

3.91 |

2.28 |

86 |

| 13,227 |

1,585 |

14.41 |

12.83 |

7.48 |

189 |

| HM-8T |

8,000 |

8,000 / 8 |

4.54 |

3.93 |

2.52 |

104 |

| 17,636 |

2,113 |

14.91 |

12.91 |

8.27 |

230 |

| HM-10T |

10,000 |

10,000 / 10 |

5.18 |

4.49 |

2.70 |

130 |

| 22,046 |

2,641 |

17.0 |

14.75 |

8.90 |

286 |

| HM-12.5T |

12,500 |

12,500/ 12.5 |

5.43 |

4.62 |

2.86 |

154 |

| 27,558 |

3,302 |

17.91 |

15.16 |

9.39 |

340 |

| HM-15T |

15,000 |

15,000 / 15 |

6.24 |

5.48 |

2.95 |

159 |

| 33,069 |

3,962 |

20.50 |

18.00 |

9.70 |

350 |

| HM-20T |

20,000 |

20,000 / 20 |

6.78 |

6. 04 |

3.42 |

224 |

| 44,100 |

5,283 |

22.25 |

19.83 |

11.25 |

492 |

| HM-25T |

25,000 |

25,000 / 25 |

7.51 |

6.40 |

3.75 |

315 |

| 55,115 |

6,604 |

24.66 |

21.0 |

12.33 |

695 |

| *HM-35T |

35,000 |

35,000 / 35 |

8.07 |

7.11 |

3.91 |

417 |

| 77,161 |

9,246 |

26.50 |

23.33 |

12.83 |

920 |

| HM-40T |

40,000 |

40,000 / 40 |

8.71 |

7.72 |

4.07 |

440 |

| 88,184 |

10,566 |

28.58 |

25.33 |

13.36 |

970 |

| HM-50T |

50,000 |

50,000 / 50 |

8.99 |

7.77 |

4.56 |

544 |

| 110,231 |

13,208 |

29.50 |

25.50 |

14.96 |

1200 |

|

HM-100T

|

100,000 |

100,000 / 100 |

11.27 |

10.00 |

5.65 |

952 |

| 220,462 |

26,420 |

37.00 |

32.9 |

18.56 |

2100 |

Features

1. Load Capacity: Load testing water bags typically have a specified load capacity that indicates the maximum weight they can hold. This allows users to determine if the water bag is suitable for their load testing needs.

2.Durable Construction: A high-quality load testing water bag is typically made from durable materials such as reinforced PVC or nylon. These materials are designed to withstand the weight and pressure of the load being tested.

3. Multiple Attachment Points: Load testing water bags usually have multiple attachment points, such as D-rings or straps, that allow for secure and stable attachment to the load being tested. These attachment points ensure that the water bag remains in place during the testing process.

4. Easy Filling and Emptying: Load testing water bags often come with a large fill port that allows for easy filling and emptying of the bag. Some bags may also have a built-in valve or spout for more convenient water drainage.

5. Handles or lifting straps: Load testing water bags may include handles or lifting straps to facilitate easy transportation and positioning of the bag during testing. These handles or straps should be designed to withstand the weight of the water-filled bag.

6. Pressure Relief Valve: Some load testing water bags may also feature a pressure relief valve to prevent over-filling or bursting of the bag. This valve allows excess pressure to be released, ensuring the safe use of the water bag.

7. Reflective Strips or Visibility Features: Load testing water bags often have reflective strips or other visibility features to enhance safety, particularly when working in low light conditions or at night.

8. Compact Storage: Many load testing water bags can be deflated and folded or rolled up for compact storage when not in use. This makes them easy to transport and store.

Applications

- Structural Load Testing

- Proof Load Testing

- Offshore Load Testing

- Material Testing

- Ship Load Testing

- Industrial Equipment Testing

- Research and Development

Advantages

◆ Reliable and Accurate Results

◆ Quality Assurance

◆ Safety Assurance

◆ Compliance with Regulations

◆ Customer Confidence

◆ Cost and Time Savings

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!