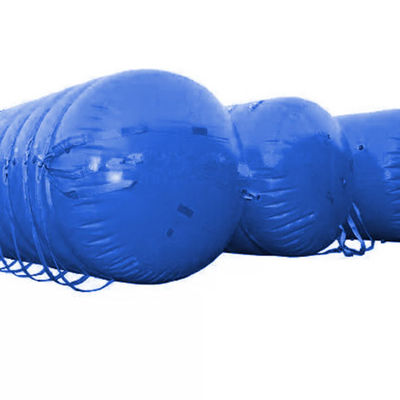

Heavy Duty Inflatable Air Bags Industrial Boat Lifting Airbags for Underwater Operations

Description

Heavy Duty Inflatable Air Bags are innovative tools designed for various applications, ranging from lifting and moving heavy objects to providing temporary support in construction and transportation settings. These durable inflatable bags are engineered to withstand significant loads while maintaining a lightweight design that makes them easy to transport and deploy. Constructed from robust materials, they offer remarkable strength, flexibility, and resilience, making them ideal for both indoor and outdoor operations.

These air bags feature advanced inflation technology that allows for rapid deployment and precise control over inflation levels. Users can easily adjust the air pressure to achieve the desired lifting capacity, accommodating a wide range of applications, including vehicle recovery, bridge construction, and heavy machinery relocation. The ability to stack or arrange the bags in various configurations also enhances their versatility, making them essential tools for contractors, emergency responders, and industrial workers alike. As industries continue to evolve, Heavy Duty Inflatable Air Bags provide reliable solutions that enhance efficiency, safety, and effectiveness on the job.

Specifications

| Model |

Lifting Capacity |

Dimensions |

Appr. Weight |

| Parachute |

[kg] |

[lbs] |

[mm] |

[kg] |

| HM-P01 |

200 |

441 |

800 |

5 |

| HM-P02 |

500 |

1,103 |

1,000 |

8 |

| HM-P03 |

1,000 |

2,205 |

1,300 |

11 |

| HM-P04 |

2,000 |

4,410 |

1,600 |

20 |

| HM-P05 |

4,000 |

8,820 |

2,000 |

50 |

| HM-P06 |

6,000 |

13,230 |

2,300 |

66 |

| HM-P07 |

8,000 |

17,640 |

2,500 |

75 |

| HM-P08 |

10,000 |

22,050 |

2,700 |

80 |

| HM-P09 |

15,000 |

33,075 |

3,100 |

110 |

| HM-P10 |

20,000 |

44,100 |

3,400 |

130 |

| HM-P11 |

30,000 |

66,150 |

3,900 |

170 |

| HM-P12 |

50,000 |

110,250 |

4,600 |

220 |

| HM-P13 |

70,000 |

154,350 |

5,200 |

310 |

| HM-P14 |

100,000 |

220,500 |

5,800 |

450 |

| HM-P15 |

150,000 |

330,750 |

6,600 |

660 |

| HM-P16 |

200,000 |

441,000 |

7,300 |

900 |

| *Note: Other sizes can be customized according to the requirements. |

| Model |

Buoyancy |

Diameter |

Length |

Appr. Weight |

| Cylindrical |

[kg] |

[lbs] |

[mm] |

[mm] |

[kg] |

| HM-C01 |

200 |

441 |

500 |

1,000 |

5 |

| HM-C02 |

500 |

1,103 |

800 |

1,000 |

8 |

| HM-C03 |

1,000 |

2,205 |

1,000 |

1,500 |

11 |

| HM-C04 |

2,000 |

4,410 |

1,300 |

1,500 |

20 |

| HM-C05 |

4,000 |

8,820 |

1,600 |

2,000 |

50 |

| HM-C06 |

6,000 |

13,230 |

2,000 |

2,000 |

66 |

| HM-C07 |

8,000 |

17,640 |

2,000 |

2,600 |

75 |

| HM-C08 |

10,000 |

22,050 |

2,400 |

2,400 |

80 |

| HM-C09 |

15,000 |

33,075 |

2,600 |

3,000 |

110 |

| HM-C10 |

20,000 |

44,100 |

3,000 |

3,000 |

130 |

| HM-C11 |

30,000 |

66,150 |

3,000 |

4,500 |

170 |

| HM-C12 |

50,000 |

110,250 |

4,000 |

4,000 |

220 |

| HM-C13 |

70,000 |

154,350 |

4,000 |

5,700 |

310 |

| HM-C14 |

100,000 |

220,500 |

4,000 |

8,000 |

450 |

| HM-C15 |

150,000 |

330,750 |

5,000 |

8,000 |

660 |

| HM-C16 |

200,000 |

441,000 |

5,000 |

10,000 |

900 |

| *Note: Other sizes can be customized according to the requirements. |

|

Model

|

Capacity

|

Length

|

Width

|

|

Pillow

|

[kg]

|

[lbs]

|

[mm]

|

[mm]

|

| HM-P100 |

100 |

220 |

1,020 |

760 |

| HM-P250 |

250 |

550 |

1,320 |

820 |

| HM-P500 |

500 |

1,100 |

1,300 |

1,200 |

| HM-P1000 |

1,000 |

2,200 |

1,550 |

1,420 |

| HM-P2000 |

2,000 |

4,400 |

1,950 |

1,780 |

| HM-P3000 |

3,000 |

6,600 |

2,900 |

1,950 |

| HM-P5000 |

5,000 |

11,000 |

3,230 |

2,030 |

| *Note: Other sizes can be customized according to the requirements. |

Features

Innovative Design

Heavy Duty Inflatable Air Bags showcase cutting-edge engineering that prioritizes both performance and usability. Their innovative design allows for effective lifting capabilities while ensuring maximum safety for operators, making them a preferred choice for lifting tasks.

Ergonomic Handling

These air bags are designed for ergonomic handling, allowing personnel to manage them comfortably and efficiently. This ergonomic focus reduces strain during operation, promoting better work practices among users.

High Visibility

Many Heavy Duty Inflatable Air Bags come in bright colors, enhancing visibility on job sites. This feature is particularly important in dynamic environments, as it helps keep operators aware of their surroundings and promotes safety.

Compatibility with Other Equipment

Heavy Duty Inflatable Air Bags can be easily integrated with other lifting and support systems. Their compatibility enhances operational flexibility, allowing users to create multi-faceted lifting solutions tailored to specific tasks and challenges.

Applications

● Floating submerged pipelines for repair

● Marine archeological excavations

● Recovering lost fishing gear

● Underwater habitat construction

● Bridge construction over water

● Offshore platform maintenance

● Flood response operations

● Underwater environmental clean-up

Advantages

Innovative Design

Our engineering team continually works on innovative designs that enhance the performance and usability of our Heavy Duty Inflatable Air Bags. By staying ahead of industry trends and customer needs, we create products that feature the latest design improvements, ensuring they are not only effective but also user-friendly. Our commitment to innovation drives us to consistently develop better solutions for our customers.

Comprehensive Testing

We subject our inflatable air bags to a rigorous testing process to ensure their safety and effectiveness. Each product undergoes a series of performance tests, including pressure testing, durability assessments, and environmental checks. This thorough evaluation guarantees that our air bags can perform reliably in real-world applications, giving our customers confidence in their purchase.

Global Reach

With a reputation that extends beyond local borders, we export our Heavy Duty Inflatable Air Bags to various countries around the world. Our ability to meet international quality standards allows us to serve a diverse clientele, expanding our market presence globally. This global reach not only diversifies our customer base but also enhances our understanding of different market demands.

Industry Leadership

As a leading manufacturer in the inflatable air bag sector, we continuously strive to maintain our position through improvements in product development and customer service. We actively participate in industry trade shows and technical conferences, sharing insights and staying connected with industry advancements. Our leadership in the field drives us to set new benchmarks in quality and innovation.

FAQ

Q1: How do I maintain my Heavy Duty Inflatable Air Bags?

A1: To maintain your air bags, inspect them regularly for signs of wear, damage, or punctures. Clean them with mild soap and water after use, especially if they have been exposed to saltwater or chemicals, and store them in a cool, dry place away from direct sunlight.

Q2: Is there a lifespan for these inflatable air bags?

A2: While the lifespan can vary based on usage and environmental conditions, our Heavy Duty Inflatable Air Bags are designed for long-term durability. With proper maintenance and care, they can effectively last many years.

Q3: What should I do if my air bag develops a leak?

A3: If a leak is detected, it’s essential to stop using the air bag immediately. Small punctures can often be repaired with a patch kit specifically designed for inflatable products. For significant damage, contact our customer support for guidance and possible repairs.

Q4: Can I store the air bags outdoors?

A4: It is best to store Heavy Duty Inflatable Air Bags indoors in a dry, temperature-controlled environment. If outdoor storage is necessary, use protective covers to shield them from UV rays and harsh weather conditions, which can affect their integrity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!