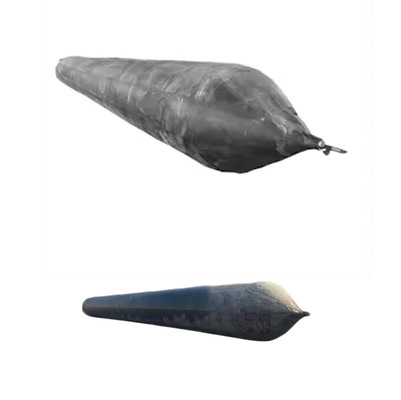

Inflatable Marine Airbags Robust Material Corrosion Resistance Reusable

Marine Rubber Airbags are an advanced, portable system for launching, hauling, and lifting ships and heavy marine structures. They are widely recognized for replacing traditional fixed launching systems, reducing project costs, and improving operational flexibility. These airbags are built from high-strength natural rubber and reinforced cord fabric to provide superior elasticity, pressure resistance, and safety.

Unlike dry docks or slipways that require heavy investment and permanent infrastructure, Marine Rubber Airbags can be deployed quickly and reused for multiple operations. Their cylindrical shape distributes force evenly, ensuring smooth rolling and minimal stress on the vessel hull or structural components.

Case Study

In 2024, an Indonesian shipyard used 15 Marine Rubber Airbags to haul a 4,000-ton coastal cargo vessel ashore for major hull repairs. The shipyard lacked a dry dock, but by preparing a compacted sand pathway and positioning the airbags correctly, the team successfully rolled the vessel onto shore in less than 10 hours. This avoided weeks of downtime and saved the shipowner over 35% in total costs compared to renting a floating dock. The operation also minimized environmental impact, as no permanent structures were built.

This case illustrates how Marine Rubber Airbags deliver practical, eco-friendly solutions to shipyards and marine contractors facing infrastructure limitations.

Specifications

| Product Name |

Marine Rubber Airbags |

| Keywords |

Marine Airbag for Ship Launching |

| Material |

100% High Tensile NR |

| Dimensions |

Diameter 0.5m - 3.0m, Length 3.0m - 28.0m, or As Request |

| Working Pressure |

0.05-0.25MPA |

| Technology |

Overall Winding, High Pressure, Explosion-proof |

| Metal Parts |

Q355 / SS304 / SS316 |

| OEM |

Supported |

| MOQ |

1 |

| Repair Tools |

Electric Heating Plate, Repair Materials, Glue, Free of Charge |

| Standard |

ISO14409:2011 |

| Certificate |

ABS, BV, KR, LR, GL, NK, RINA, DNV, RMRS |

| Package |

Pallets, Wooden Cases |

| Service Life |

20 Years |

| Warranty |

36 Months |

Performance Data

| Diameter |

Working Pressure |

Working Height |

Bearing Capacity (KN/m) |

Bearing Capacity (Ton/m) |

| D=1.0m |

0.14Mpa |

0.6m |

87.96 |

8.98 |

| 0.5m |

|

|

109.96 |

11.22 |

| 0.4m |

|

|

131.95 |

13.46 |

| D=1.2m |

0.12Mpa |

0.7m |

94.25 |

9.62 |

| 0.6m |

|

|

113.10 |

11.54 |

| 0.5m |

|

|

131.95 |

13.46 |

| 0.4m |

|

|

150.80 |

15.39 |

| D=1.5m |

0.10Mpa |

0.9m |

94.25 |

9.62 |

| 0.8m |

|

|

109.96 |

11.22 |

| 0.7m |

|

|

125.66 |

12.82 |

| 0.6m |

|

|

141.37 |

14.43 |

| 0.5m |

|

|

157.08 |

16.03 |

| D=1.8m |

0.09Mpa |

1.1m |

98.96 |

10.10 |

| 1.0m |

|

|

113.10 |

11.54 |

| 0.9m |

|

|

127.33 |

12.98 |

| 0.8m |

|

|

141.37 |

14.43 |

| 0.7m |

|

|

155.51 |

15.87 |

| 0.6m |

|

|

169.65 |

17.31 |

| D=2.0m |

0.08Mpa |

1.2m |

100.53 |

10.26 |

| 1.1m |

|

|

113.10 |

11.54 |

| 1.0m |

|

|

125.66 |

12.82 |

| 0.9m |

|

|

138.23 |

14.11 |

| 0.8m |

|

|

150.80 |

15.39 |

| 0.7m |

|

|

163.36 |

16.67 |

| 0.6m |

|

|

175.93 |

17.95 |

* Other size can be provided follow client's requirements.

Features

- Superior Load Capacity with Safe Rolling Action

Marine Rubber Airbags are engineered to handle vessels weighing from hundreds to tens of thousands of tons. Their layered construction of rubber and synthetic cord fabric resists deformation under high working pressures. Combined with their cylindrical geometry, this ensures safe rolling and even load distribution during launches or heavy lifts.

- Long Service Life and Weather Durability

The external rubber layers are formulated for resistance to abrasion, ozone, and UV degradation. They also withstand saltwater and chemical exposure in harsh marine environments. With routine inspections and proper storage, Marine Rubber Airbags can reliably serve for over a decade.

- Rapid Deployment and Transportability

Marine Rubber Airbags are lightweight and rollable, making them easy to transport and deploy at multiple locations. A small team can position and inflate the airbags within hours, eliminating the need for costly fixed facilities. This flexibility maximizes utilization and minimizes downtime.

- Built In Safety Features

High-friction surfaces provide stability during vessel movement. Operators can adjust internal pressure to control lifting force and rolling speed. Optional overpressure valves and protective mats further enhance operational safety, reducing risk of accidents or damage.

Applications

- Ship Launching and Recovery

Ideal for launching new vessels and hauling them ashore for inspection, maintenance, or retrofitting. Suitable for fishing boats, ferries, barges, and offshore platforms.

- Heavy Equipment and Structure Movement

Used to relocate floating docks, large industrial modules, or bridge sections onshore or offshore. Their portability makes them ideal for temporary or remote project sites.

- Emergency Salvage Operations

Provide buoyancy to refloat sunken vessels or stabilize damaged structures. Quick inflation enables rapid response during emergencies.

Why Choose Hongruntong Marine?

Decades of Experience and Custom Solutions

Hongruntong Marine has over 20 years of expertise in Marine Rubber Airbag design and manufacturing. Our R&D team uses advanced simulation and testing to optimize load capacity, safety margins, and material performance. We offer customized sizes, diameters, and working pressures tailored to each customer's project.

ISO Certified Production and Strict Quality Control

We use premium-grade natural rubber and high-tensile synthetic cord fabric, manufactured in ISO 9001-certified facilities. Automated winding and vulcanization ensure consistency and strength. Every airbag undergoes rigorous pressure, leakage, and seam integrity tests before delivery, guaranteeing safe and reliable performance.

Proven Global Track Record

Hongruntong Marine has successfully supplied Marine Rubber Airbags to shipyards, offshore projects, and salvage teams in over 35 countries. In 2023, our airbags were used to refloat a grounded tanker in the Middle East, completing the operation within 48 hours and saving millions in potential losses. These global successes confirm the reliability and efficiency of our products.

Comprehensive Customer and After Sales Support

We provide detailed operation manuals, on-site training, and spare parts for maintenance. Our technical experts assist in project planning, deployment, and troubleshooting to ensure safe and efficient use. This full-service approach extends product life and maximizes customer investment, establishing long-term partnerships worldwide.

FAQ

1. What sizes and load capacities are available?

We offer airbags in diameters from 0.8m to 2.5m and lengths from 5m to 24m, with working pressures up to 0.25MPa. Multiple airbags can be combined to handle vessels exceeding 25,000 tons.

2. How do you prepare the site for airbag launching?

The ground should be compacted and leveled, with protective mats or wooden planks on rough surfaces. Deflated airbags are positioned under the vessel hull, then gradually inflated to lift and roll the vessel toward the water.

3. How long do Marine Rubber Airbags last?

With proper maintenance--rinsing with fresh water after use, inspecting seams and valves, and storing deflated in a cool, dry place service life typically exceeds 10 years.

4. Can airbags be used for salvage and offshore projects?

Yes. Marine Rubber Airbags provide buoyancy and lifting capacity for salvage operations, pipeline installation, and offshore construction. Their rapid deployment and high pressure resistance make them ideal for challenging environments.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!