Hydrostatic Load Bags: Reliable Performance, Easy Handling, Reduced Test Time, Durable

Product Overview

Load Testing Water Bags are specialized devices used to simulate precise structural loads in civil engineering, industrial platforms, and heavy equipment testing. Unlike static weights, these water bags allow controlled, uniform load application, reducing setup time and improving safety.

Constructed with reinforced high-strength rubber layers, they resist abrasion, tearing, and high-pressure stress while remaining flexible to adapt to uneven surfaces. The bags are designed for portability, rapid filling, and easy deployment, making them ideal for temporary or remote testing sites.

Case Study

In 2022, a construction company in Canada used 20 Load Testing Water Bags to verify the load-bearing capacity of a temporary industrial platform supporting 150-ton machinery. The platform had no permanent support system, so conventional weights were impractical.

The bags were evenly spaced under the platform, gradually filled with water, and monitored with load sensors. The test confirmed that the platform could safely support the machinery, while water discharge and bag removal were completed efficiently. This solution saved weeks of labor and reduced risk compared to conventional steel weights.

The successful project demonstrated that Load Testing Water Bags are reliable, safe, and efficient for high-capacity temporary load testing in challenging environments.

Specifications

| Name |

Load Testing Water Bags |

| Application |

Proof Load Testing, Offshore Load Testing, Structural Load Testing, Ship Load Testing, Industrial Equipment Testing, Research and Development |

| Content |

100% POLYVINYL CHLORIDE |

| Phthalate |

7P Phthalate Free (includes all Phthalates listed in CAL Prop 65, CPSIA and REACH) |

| Backing Material Size |

1.8/2.0 MM X 1.55M, thickness Produced as Per Your Request |

| Weight |

37.1 oz square yard/ 1450 +- 50 GSM |

| Special |

UV Resistant

7P Phthalate Free (Includes all Phthalates Listed in CAL Prop 65, CPSIA and REACH)

BPA Free / Tris Free / Formaldehyde Free

Does Not Contain Conflict Minerals |

| Care Instructions |

Rinse with Fresh Water and Air Dry

Do Not Store with Seawater and Keep Away from Heat Sources |

| Available sizes |

5000 kg, 8,000 kg, 1,0000 kg, 15,000 kg, 20,000 kg, 30,000 kg, 50,000 kg, 100,000 kg

Special Sizes Could be Customized |

| OEM |

Supported |

Technical Specifications

| MODEL |

Weight |

Volume |

Empty Height (Length) |

Filled Height (Length) |

Max Diam ( ø) |

Dry Weight without accessories |

| HM-1T |

1,000 kg / 2,204 lbs |

1,000 / 1 Liters / m3

264 USG |

2.52 m / 8.27 ft |

2.23 m / 7.33 ft |

1.39 m / 4.56 ft |

36 kg / 80 lbs |

Key Features

Precise Load Control

Load Testing Water Bags allow engineers to simulate exact weights by adjusting the water volume. This precision ensures uniform load distribution across structures like bridges, roofs, or platforms, allowing accurate deflection and stress measurements.

Robust and Durable Construction

Made from abrasion-resistant rubber with multi-layer cord reinforcement, the bags can withstand repeated filling, high-pressure operation, and rough surfaces. UV and chemical resistance extend the lifespan, ensuring reliable performance in outdoor and industrial environments.

Portable and Easy to Deploy

Lightweight when empty, the bags can be transported by small teams and quickly positioned on-site. Modular sizes allow customization to specific load requirements, while cylindrical designs conform to uneven surfaces for optimal stability.

Safe and Controlled Operation

Leak-proof seams, reinforced valves, and controlled filling and drainage systems protect operators and structures. Gradual inflation and deflation prevent sudden load shifts, ensuring a safe and predictable testing process.

Applications

- Temporary Platform Load Testing: Ensure platforms, scaffolds, or industrial floors can handle planned machinery or operational loads. Water bags provide a controlled and repeatable test method.

- Bridge Stress Verification: Simulate live traffic loads and verify deflection and stress parameters. Adjustable water volume allows precise replication of varying traffic or environmental loads.

- Crane and Hoist Calibration: Provide controlled weights to certify lifting equipment, test load limits, and ensure safety compliance. Rapid deployment reduces downtime for equipment testing.

Why Choose Hongruntong Marine

Extensive Engineering Expertise

With over 20 years of experience, Hongruntong Marine designs Load Testing Water Bags optimized for precise structural testing. Our R&D team ensures each bag meets rigorous performance, safety, and durability standards.

Premium Manufacturing Standards

All bags are produced using high-strength rubber and multi-layer cord reinforcement in ISO-certified facilities. Automated production ensures consistent thickness, leak-proof seams, and long-term reliability.

Proven International Track Record

Our water bags have been used in over 35 countries for bridges, industrial platforms, and crane testing. Projects in North America and Europe validate their effectiveness, safety, and efficiency under real engineering conditions.

Full Customer Support and After Sales Service

Hongruntong Marine provides detailed operation manuals, on-site technical guidance, and maintenance advice. Spare parts, repair kits, and responsive support extend the lifespan of each water bag while ensuring safe operation.

Frequently Asked Questions

1. What load capacities are supported?

Available from 1 ton to several hundred tons. Multiple bags can be combined for larger structures.

2. How do I set up bags for platform testing?

Position bags evenly, ensure surfaces are stable, then fill gradually. Use sensors to monitor load distribution.

3. Are these bags reusable?

Yes, high-quality rubber allows multiple uses. Inspect for leaks and rinse after each test.

4. Can they be used outdoors?

Yes, UV and corrosion-resistant materials allow outdoor deployment.

5. How is water safely discharged?

Controlled valves allow gradual draining to prevent sudden load shifts and ensure operator safety.

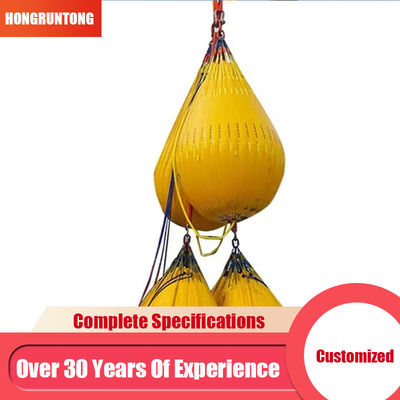

Product Images

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!