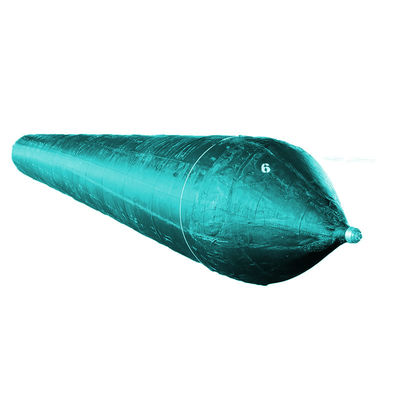

Marine Rubber Airbag Lifting Airbag Salvage Rubber Airbags for Vessel Relocation

Description

Tugging Marine Rubber Airbag Our Tugging Marine Rubber Airbags are specifically designed for towing and transporting large vessels or structures. With reinforced rubber and fabric layers, these airbags offer superior strength and durability to withstand the stress of continuous tugging operations in tough marine environments.

Hongruntong Marine’s tugging airbags provide excellent buoyancy and balance, ensuring safe and efficient transport of vessels in both calm and rough waters. Their robust construction guarantees a long service life, even under extreme conditions.

Specifications

| Item |

Description |

| Place of Origin |

China |

| Brand Name |

Hongruntong Marine |

| Material |

NBR |

| Diameter |

0.5m-3.0m, or as Request |

| Length |

1.0m-28.0m, or as Request |

| Working Pressure |

0.05-0.25 mpa |

| Technics |

High pressure, overall winding, explosion-proof |

| Use |

ship launching and docking |

| Thickness |

5-13 ply |

| Standard |

Conducted by ISO14409 and GB/T1590-2006 system. |

| Accessories |

Q355/SS304/SS316, Pressure Gauge, Tee, Plug, Switch, Inflation Tube |

| Packaging |

Inner-Plastic Bag; Outer-Standard Wooden Pallets. |

| Keywords |

Rubber Airbag |

| Certificates |

ABS, BV, KR, LR, GL, NK, RINA, DNV, RMRS |

| MOQ |

1 |

| OEM |

Welcome |

| Diameter |

Working

Pressure

|

Working

Height

|

Bearing Capacity |

| KN/m |

Ton/m |

| D=1.0m |

0.14Mpa |

0.6m |

87.96 |

8.98 |

| 0.5m |

109.96 |

11.22 |

| 0.4m |

131.95 |

13.46 |

| D=1.2m |

0.12Mpa |

0.7m |

94.25 |

9.62 |

| 0.6m |

113.10 |

11.54 |

| 0.5m |

131.95 |

13.46 |

| 0.4m |

150.80 |

15.39 |

| D=1.5m |

0.10Mpa |

0.9m |

94.25 |

9.62 |

| 0.8m |

109.96 |

11.22 |

| 0.7m |

125.66 |

12.82 |

| 0.6m |

141.37 |

14.43 |

| 0.5m |

157.08 |

16.03 |

| D=1.8m |

0.09Mpa |

1.1m |

98.96 |

10.10 |

| 1.0m |

113.10 |

11.54 |

| 0.9m |

127.33 |

12.98 |

| 0.8m |

141.37 |

14.43 |

| 0.7m |

155.51 |

15.87 |

| 0.6m |

169.65 |

17.31 |

| D=2.0m |

0.08Mpa |

1.2m |

100.53 |

10.26 |

| 1.1m |

113.10 |

11.54 |

| 1.0m |

125.66 |

12.82 |

| 0.9m |

138.23 |

14.11 |

| 0.8m |

150.80 |

15.39 |

| 0.7m |

163.36 |

16.67 |

| 0.6m |

175.93 |

17.95 |

| * Other size can be produced follow client's requirements. |

Features

Floating Crane Support

Provides buoyancy support for floating crane operations.

Mooring Assistance

Helps stabilize vessels during docking or mooring operations.

Temporary Dry Docking

Provides temporary buoyancy for vessels under repair or maintenance.

Bridge Construction

Used in marine bridge construction for lifting and positioning heavy components.

Offshore Platform Relocation

Ideal for relocating large offshore platforms in offshore oil and gas operations.

Applications

● Large vessel relocation

● Offshore construction support

● Floating platform positioning

Advantages

High Pressure Resistance

Airbags designed to handle high pressure without compromising performance.

Anti Corrosion Properties

Resistant to corrosion from seawater, ensuring longevity and durability.

User Friendly Design

Easy to operate and maintain, even in challenging marine environments.

Stable Performance

Consistent performance under different conditions, including rough seas and extreme weather.

FAQ

1. Can Marine Rubber Airbags be repaired?

Yes, minor damage like small punctures can often be repaired using special rubber repair kits, but larger damage may require replacing the airbag.

2. How are Marine Rubber Airbags different from air cushions?

Marine Rubber Airbags are designed specifically for marine environments and heavy lifting, whereas air cushions are typically used for lighter, more precise load movements in non marine contexts.

3. What are the advantages of using Marine Rubber Airbags over traditional methods?

Marine Rubber Airbags are flexible, portable, require less setup time, and can be used in various environmental conditions, making them a versatile solution.

4. How do Marine Rubber Airbags contribute to environmental sustainability?

They help reduce the need for heavy machinery, which lowers energy consumption and reduces the environmental impact of large lifting operations.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!