Pillow Size Air Valves Flotation Bags Underwater Air Lifting Bag Boat Lift Air Bags

Description

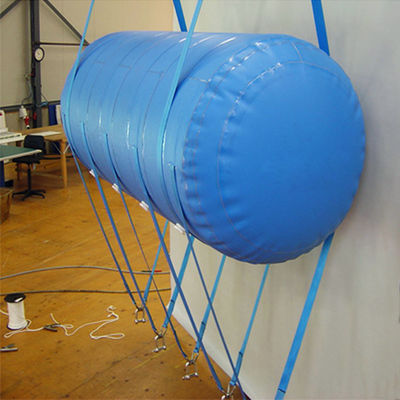

Underwater Air Lift Bags, also known as lift bags or salvage bags, are inflatable devices used in underwater operations to lift heavy objects to the surface. These bags are essential tools in various industries, including marine salvage, offshore construction, and underwater research. The main purpose of an Underwater Air Lift Bag is to generate buoyancy and provide vertical lift in underwater environments. Made from durable materials such as high-strength fabrics or synthetic rubber, these bags are designed to withstand harsh conditions and high pressure depths. They can accommodate various capacities, ranging from a few kilograms to several metric tons.

The operation of an Underwater Air Lift Bag is relatively straightforward. Compressed air is pumped into the bag, displacing the surrounding water and resulting in buoyancy. By adding or releasing air, the buoyancy can be adjusted, allowing for controlled ascent or descent. The bags are usually equipped with valves for easy inflation and deflation. Underwater Air Lift Bags offer many advantages in underwater operations. They provide a cost-effective and efficient method for lifting heavy objects without the need for complex machinery or infrastructure. Moreover, they are versatile and can be easily transported, making them ideal for remote or challenging underwater locations.

In conclusion, Underwater Air Lift Bags play a crucial role in underwater operations, offering a reliable and versatile solution for lifting heavy objects. Their simplicity, durability, and effectiveness make them indispensable tools in various industries where underwater tasks are involved.

Specifications

| Product Name |

Underwater Air Lift Bags, Air Lifting Bags |

| Raw Material |

Superior PVC Coating Fabric |

| Type |

Cylindrical, Parachute, Pillow |

| Size |

500kg, 1000kg, 5000kg 10000kg,etc |

| Thickness |

0.4-1.2mm, or as request |

| Color |

Yellow,Blue,Black,etc |

| Density |

0.33-0.9g/cm3 |

| Safety Factor |

7:1 |

| Accessories |

Valve, Inflatable Tube, Repair Material |

| OEM |

Welcome |

| Warranty |

3 Years |

|

Tolerances

|

+/- 0.03 on densities

+/- 0.2 mm on thickness

+/- 0 to +3mm on width

+/- 0 to +3mm on length

|

| Model |

Lifting Capacity |

Dimensions |

Appr. Weight |

| Parachute |

[kg] |

[lbs] |

[mm] |

[kg] |

| HM-P01 |

200 |

441 |

800 |

5 |

| HM-P02 |

500 |

1,103 |

1,000 |

8 |

| HM-P03 |

1,000 |

2,205 |

1,300 |

11 |

| HM-P04 |

2,000 |

4,410 |

1,600 |

20 |

| HM-P05 |

4,000 |

8,820 |

2,000 |

50 |

| HM-P06 |

6,000 |

13,230 |

2,300 |

66 |

| HM-P07 |

8,000 |

17,640 |

2,500 |

75 |

| HM-P08 |

10,000 |

22,050 |

2,700 |

80 |

| HM-P09 |

15,000 |

33,075 |

3,100 |

110 |

| HM-P10 |

20,000 |

44,100 |

3,400 |

130 |

| HM-P11 |

30,000 |

66,150 |

3,900 |

170 |

| HM-P12 |

50,000 |

110,250 |

4,600 |

220 |

| HM-P13 |

70,000 |

154,350 |

5,200 |

310 |

| HM-P14 |

100,000 |

220,500 |

5,800 |

450 |

| HM-P15 |

150,000 |

330,750 |

6,600 |

660 |

| HM-P16 |

200,000 |

441,000 |

7,300 |

900 |

| *Note: Other sizes can be customized according to the requirements. |

| Model |

Buoyancy |

Diameter |

Length |

Appr. Weight |

| Cylindrical |

[kg] |

[lbs] |

[mm] |

[mm] |

[kg] |

| HM-C01 |

200 |

441 |

500 |

1,000 |

5 |

| HM-C02 |

500 |

1,103 |

800 |

1,000 |

8 |

| HM-C03 |

1,000 |

2,205 |

1,000 |

1,500 |

11 |

| HM-C04 |

2,000 |

4,410 |

1,300 |

1,500 |

20 |

| HM-C05 |

4,000 |

8,820 |

1,600 |

2,000 |

50 |

| HM-C06 |

6,000 |

13,230 |

2,000 |

2,000 |

66 |

| HM-C07 |

8,000 |

17,640 |

2,000 |

2,600 |

75 |

| HM-C08 |

10,000 |

22,050 |

2,400 |

2,400 |

80 |

| HM-C09 |

15,000 |

33,075 |

2,600 |

3,000 |

110 |

| HM-C10 |

20,000 |

44,100 |

3,000 |

3,000 |

130 |

| HM-C11 |

30,000 |

66,150 |

3,000 |

4,500 |

170 |

| HM-C12 |

50,000 |

110,250 |

4,000 |

4,000 |

220 |

| HM-C13 |

70,000 |

154,350 |

4,000 |

5,700 |

310 |

| HM-C14 |

100,000 |

220,500 |

4,000 |

8,000 |

450 |

| HM-C15 |

150,000 |

330,750 |

5,000 |

8,000 |

660 |

| HM-C16 |

200,000 |

441,000 |

5,000 |

10,000 |

900 |

| *Note: Other sizes can be customized according to the requirements. |

|

Model

|

Capacity

|

Length

|

Width

|

|

Pillow

|

[kg]

|

[lbs]

|

[mm]

|

[mm]

|

| HM-P100 |

100 |

220 |

1,020 |

760 |

| HM-P250 |

250 |

550 |

1,320 |

820 |

| HM-P500 |

500 |

1,100 |

1,300 |

1,200 |

| HM-P1000 |

1,000 |

2,200 |

1,550 |

1,420 |

| HM-P2000 |

2,000 |

4,400 |

1,950 |

1,780 |

| HM-P3000 |

3,000 |

6,600 |

2,900 |

1,950 |

| HM-P5000 |

5,000 |

11,000 |

3,230 |

2,030 |

| *Note: Other sizes can be customized according to the requirements. |

Features

High performance

Our Underwater Air Lift Bags are designed with advanced technology and materials, ensuring superior performance in lifting and salvage operations. They are built to withstand extreme underwater conditions and have a high lifting capacity that allows for efficient and safe operations.

Durable construction

Our bags are made from premium-quality, durable materials that resist punctures, tears, and degradation over time. The robust construction ensures the bags can withstand the rigors of underwater use, making them reliable and long-lasting.

Versatility

Our Underwater Air Lift Bags are available in a range of sizes and capacities to meet diverse lifting and salvage requirements. Whether it's for shallow water operations or deep-sea recovery, our bags are designed to provide the necessary buoyancy and stability for a wide range of underwater tasks.

Safety features

Safety is our top priority, and our Underwater Air Lift Bags are equipped with a range of features to ensure safe and efficient operations. This includes reinforced straps, secure attachment points, and pressure relief valves that prevent over-inflation. These features minimize the risk of accidents and ensure the well-being of divers and crew involved in underwater operations.

Applications

● Salvage operations

● Marine construction

● Offshore drilling operations

● Underwater pipeline installation

● Dredging operations

● Shipwreck recovery

● Underwater vehicle recovery

● Submarine rescue operations

● Underwater archaeology

● Underwater infrastructure maintenance

Advantages

Extensive Manufacturing Experience

With over 30 years of manufacturing experience, we have developed a deep understanding of the product and its requirements. This allows us to consistently produce high-quality Underwater Air Lift Bags that meet industry standards.

Advanced Technology and Equipment

Our factory is equipped with state-of-the-art technology and advanced manufacturing equipment. This enables us to streamline the production process, improve efficiency, and ensure precision in every stage of manufacturing.

Customization and Flexibility

We understand that different customers may have specific requirements for Underwater Air Lift Bags. We offer customization options to tailor the products according to our customers' needs. This level of flexibility allows us to accommodate a wide range of applications and specifications.

Strong Quality Control

Quality is our top priority. We have implemented rigorous quality control measures throughout the manufacturing process. This includes thorough inspections, testing, and adherence to strict quality standards. As a result, our Underwater Air Lift Bags are known for their reliability, durability, and performance in various underwater lifting operations.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!