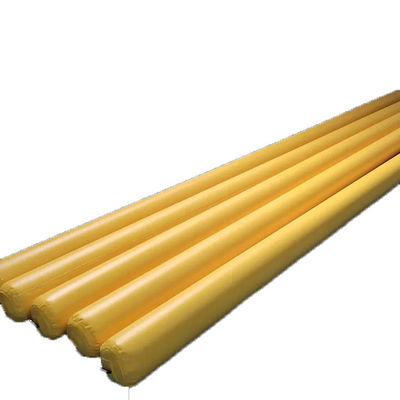

Floating Rescue Life Saving Inflatable Salvage Tubes Puncture Resistant

Description

Inflatable Salvage Tube for Emergency Marine Recovery This inflatable salvage tube is an essential tool for emergency marine recovery operations. Whether responding to a sinking vessel or retrieving valuable equipment, it offers rapid deployment and strong buoyancy. Constructed with reinforced fabrics and a puncture-resistant coating, this tube ensures safety and reliability under extreme conditions. The lightweight, compact design allows for easy storage on vessels, ready for immediate use.

Specifications

| Product Name |

Inflatable Salvage Tubes |

| Size |

As Required |

| Material |

High Performance PVC |

| Salvage Buoyancy |

50kg - 300Tons |

| Inflatable Valve |

Stainless Steel |

| Pressure Relief Valve |

HDPE |

| Warranty |

2 Years |

| Service Life |

6-10 Years |

Features

High Buoyancy

Designed to provide excellent flotation, ensuring effective support for heavy materials and equipment during salvage operations.

Durable Construction

Made from reinforced, puncture-resistant materials that withstand harsh marine conditions and rough handling.

Lightweight Design

Easy to transport and deploy, allowing for quick response in emergency situations.

Rapid Inflation

Equipped with efficient air valves for quick inflation using manual or electric pumps, saving valuable time during operations.

Applications

● Salvaging sunken vessels

● Recovering lost fishing gear

● Marine debris removal

● Underwater construction support

● Raising heavy equipment from the seabed

● Oil spill containment

● Recovering underwater artifacts

Advantages

Expertise and Experience

With over 30 years in the industry, our extensive knowledge and technical expertise ensure we produce high-quality inflatable salvage tubes that meet rigorous standards.

Superior Quality Materials

We utilize only the best, reinforced materials to create durable and reliable inflatable tubes, ensuring they withstand harsh marine environments and provide long-lasting performance.

Custom Manufacturing Solutions

We offer tailored designs to meet specific client requirements, allowing customers to choose sizes, colors, and features that cater to their unique operational needs.

Commitment to Innovation

Our ongoing investment in research and development keeps us at the forefront of technology, enabling us to incorporate advanced features and improvements into our products for enhanced functionality.

FAQ

1. What are Inflatable Salvage Tubes?

Inflatable Salvage Tubes are buoyant structures designed to assist in marine salvage operations, oil spill containment, and environmental protection.

2. What materials are Inflatable Salvage Tubes made from?

They are typically made from durable, high density polyethylene (HDPE) or nylon fabric that is coated for enhanced resistance to punctures and UV degradation.

3. What sizes do Inflatable Salvage Tubes come in?

They are available in various sizes, customized according to specific applications and client requirements.

4. How do Inflatable Salvage Tubes work?

When inflated, the tubes create buoyancy, allowing them to support loads while floating on water, thereby aiding in salvage efforts or pollution control.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!