กระเป๋าทดสอบความจางนาน ใช้งานได้นาน ทนต่ออากาศ UV

ภาพรวมสินค้า

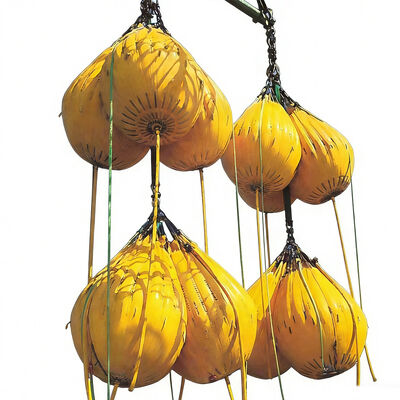

กระเป๋าน้ําทดสอบภาระ เป็นวิธีการทดสอบภาระที่มีความยืดหยุ่นและเป็นมืออาชีพที่ออกแบบมาเพื่อทดสอบภาระของอุปกรณ์ยก, โครงสร้างทางเรือ และอุปกรณ์ในทะเลโดยใช้น้ําเป็นสื่อความจุที่เปลี่ยนแปลงและควบคุมได้, กระเป๋าสะพายเหล่านี้เป็นทางเลือกที่แม่นยํา, ปลอดภัยและมีประหยัดต่อน้ําหนักแข็งแบบดั้งเดิม เช่น บล็อกเหล็กหรือคอนกรีตบัลลาสต์

ผลิตจากผ้าเทคนิคที่มีความแข็งแรงและแรงสูง กระเป๋าน้ําถูกออกแบบให้ทนความดันภายในสูงจุดติดตั้งยกหลายจุด, และระบบการเติมและการระบายน้ําที่ควบคุมให้มั่นคงทั้งความปลอดภัยในการใช้งานและความแม่นยําระหว่างวิธีการทดสอบภาระ

การศึกษากรณี

ที่โรงเรือชายฝั่งใหญ่ ที่เชี่ยวชาญในเรื่องการสร้างและบํารุงรักษาเรือบรรทุกสินค้าขนาดกลางลูกค้าถูกเรียกร้องให้ดําเนินการทดสอบภาระการทดสอบบนเครนพานที่ติดตั้งใหม่ที่มีกําลังยก 150 ตันโครงการนี้เผชิญกับข้อจํากัดหลายอย่าง: พื้นที่เก็บของที่จํากัดสําหรับน้ําหนักการทดสอบเหล็กแบบดั้งเดิม โปรแกรมการทดสอบที่เข้มงวด และการตรวจสอบความปลอดภัยอย่างเข้มงวดโดยสังคมประเภท

Hongruntong Marine จําหน่ายชุดกระเป๋าน้ําทดสอบภาระแบบโมดูลที่มีความจุสูงสุดรวมเกินภาระการทดสอบที่ต้องการกระเป๋าสะพายถูกส่งเสื่อม และขนส่งโดยตรงไปยังท่าเรือ โดยใช้รถยกแบบมาตรฐานในสถานที่ กระเป๋าถูกเชื่อมต่อโดยใช้เชือกที่ได้รับการรับรอง และค่อย ๆ เติมน้ําทะเลผ่านระบบการเติมควบคุม

ลูกค้ารายงานการลดเวลาในการทดสอบและต้นทุนทาง logistic อย่างสําคัญ เมื่อเทียบกับโครงการก่อนหน้านี้ที่ใช้น้ําหนักเหล็กเมื่อการทํางานด้วยมือและมวลของสารแข็งที่แขวนได้ลดลงอย่างน้อย.

รายละเอียด

ข้อมูลทั่วไป

| ชื่อ |

กระเป๋าน้ําทดสอบภาระ |

| การใช้งาน |

การทดสอบภาระการทดสอบ, การทดสอบภาระการทดสอบนอกทะเล, การทดสอบภาระโครงสร้าง, การทดสอบภาระการทดสอบเรือ, การทดสอบอุปกรณ์อุตสาหกรรม, การวิจัยและการพัฒนา |

| เนื้อหา |

100% โพลีไวนิลเคลอรีด |

| ธาเลต |

7P ฟาตาเลตฟรี (รวมฟาตาเลตทั้งหมดที่ระบุใน CAL Prop 65, CPSIA และ REACH) |

| ขนาดของวัสดุสนับสนุน |

1.8/2.0 MM X 1.55M, ความหนาผลิตตามคําขอของคุณ |

| น้ําหนัก |

37.1 oz ตารางยาร์ด/ 1450 +- 50 GSM |

| ลักษณะพิเศษ |

ทนต่อ UV ฟรี 7P ฟาตาเลต ฟรี BPA ฟรี Tris ฟรี ฟอร์มัลดีไฮด ฟรี ไม่มีแร่ธาตุขัดแย้ง |

| คําแนะนําในการดูแล |

ล้างด้วยน้ําหวานและแห้งด้วยอากาศ อย่าเก็บด้วยน้ําทะเล และเก็บให้ห่างจากแหล่งความร้อน |

| ขนาดที่มี |

5000 กิโลกรัม, 8,000 กิโลกรัม, 10,000 กิโลกรัม, 15,000 กิโลกรัม, 20,000 กิโลกรัม, 30,000 กิโลกรัม, 50,000 กิโลกรัม, 100,000 กิโลกรัม |

| OEM |

การสนับสนุน |

รายละเอียดเทคนิค

| HM-1T |

1,000 kg / 2,204 lbs |

1,000 L / 1 m3 / 264 USG |

2.52 เมตร / 8.27 ฟุต |

2.23 เมตร / 7.33 ฟุต |

1.39 m / 4.56 ฟุต |

36 กิโลกรัม / 80 ปอนด์ |

| HM-2T |

2,000 กิโลกรัม / 4,409 ปอนด์ |

2,000 L / 2 m3 / 528 USG |

2.87 m / 9.41 ฟุต |

2.6 m / 8.5 ฟุต |

1.65 m / 5.43 ฟุต |

41 กิโลกรัม / 90 ปอนด์ |

| HM-3T |

3,000 กิโลกรัม / 6,613 ปอนด์ |

3,000 L / 3 m3 / 792 USG |

3.38 m / 11.11 ft |

2.97 m / 9.75 ฟุต |

1.82 m / 6.0 ฟุต |

50 กิโลกรัม / 110 ปอนด์ |

| HM-4T |

4,000 กิโลกรัม / 8,818 ปอนด์ |

4,000 L / 4 m3 / 1,056 USG |

3.41 เมตร / 11.22 ฟุต |

30.07 m / 10.1 ฟุต |

1.88 m / 6.16 ฟุต |

64 กิโลกรัม / 141 ปอนด์ |

| HM-5T |

5,000 กิโลกรัม / 11,023 ปอนด์ |

5,000 L / 5 m3 / 1,320 USG |

4.14 m / 13.60 ฟุต |

3.52 เมตร / 11.58 ฟุต |

2.13 เมตร / 7.0 ฟุต |

80 กก / 176 ปอนด์ |

| HM-6T |

6,000 กิโลกรัม / 13,227 ปอนด์ |

6,000 L / 6 m3 / 1,585 USG |

4.39 m / 14.41 ฟุต |

30.91 m / 12.83 ฟุต |

2.28 m / 7.48 ฟุต |

86 กิโลกรัม |

| HM-8T |

8,000 กิโลกรัม / 17,636 ปอนด์ |

8,000 L / 8 m3 / 2,113 USG |

4.54 m / 14.91 ฟุต |

3.93 m / 12.91 ฟุต |

2.52 เมตร / 8.27 ฟุต |

104 กิโลกรัม / 230 ปอนด์ |

| HM-10T |

10,000 กิโลกรัม / 22,046 ปอนด์ |

10,000 L / 10 m3 / 2,641 USG |

5.18 เมตร / 17.0 ฟุต |

4.49 m / 14.75 ฟุต |

2.70 เมตร / 8.90 ฟุต |

130 กก / 286 ปอนด์ |

| HM-12.5T |

12500 กิโลกรัม / 27,558 ปอนด์ |

12,500 ลิตร / 12.5 m3 / 3,302 USG |

5.43 m / 17.91 ฟุต |

4.62 m / 15.16 ฟุต |

2.86 m / 9.39 ฟุต |

154 กิโลกรัม / 340 ปอนด์ |

| HM-15T |

15,000 กิโลกรัม / 33,069 ปอนด์ |

15,000 L / 15 m3 / 3,962 USG |

6.24 เมตร / 20.50 ฟุต |

5.48 เมตร / 18.00 ฟุต |

2.95 m / 9.70 ฟุต |

159 กิโลกรัม / 350 ปอนด์ |

| HM-20T |

20,000 กิโลกรัม / 44,100 ปอนด์ |

20,000 L / 20 m3 / 5,283 USG |

6.78 m / 22.25 ฟุต |

60.04 เมตร / 19.83 ฟุต |

3.42 m / 11.25 ฟุต |

224 กิโลกรัม / 492 ปอนด์ |

| HM-25T |

25,000 กิโลกรัม / 55,115 ปอนด์ |

25,000 L / 25 m3 / 6,604 USG |

7.51 เมตร / 24.66 ฟุต |

6.40 m / 21.0 ฟุต |

3.75 m / 12.33 ฟุต |

315 kg / 695 lbs |

| HM-35T |

35,000 กิโลกรัม / 77,161 ปอนด์ |

35,000 L / 35 m3 / 9,246 USG |

8.07 m / 26.50 ฟุต |

7.11 เมตร / 23.33 ฟุต |

30.91 m / 12.83 ฟุต |

417 กิโลกรัม / 920 ปอนด์ |

| HM-40T |

40,000 กิโลกรัม / 88,184 ปอนด์ |

40,000 L / 40 m3 / 10,566 USG |

8.71 m / 28.58 ฟุต |

7.72 m / 25.33 ฟุต |

40.07 เมตร / 13.36 ฟุต |

440 กิโลกรัม |

| HM-50T |

50,000 กิโลกรัม / 110,231 ปอนด์ |

50,000 L / 50 m3 / 13,208 USG |

80.99 m / 29.50 ฟุต |

7.77 m / 25.50 ฟุต |

4.56 m / 14.96 ft |

544 กิโลกรัม / 1200 ปอนด์ |

| HM-100T |

100,000 กิโลกรัม / 220,462 ปอนด์ |

100,000 L / 100 m3 / 26,420 USG |

11.27 m / 37.00 ft |

10.00 m / 32.9 ฟุต |

5.65 เมตร / 18.56 ฟุต |

952 กิโลกรัม / 2100 ปอนด์ |

ลักษณะสําคัญ

ความสามารถในการบรรทุกภาระสูง พร้อมความมั่นคงทางโครงสร้าง

การทดสอบภาระ ถุงน้ําถูกออกแบบมาเพื่อจัดการกับภาระที่มีความแข็งแกร่งสูงในขณะที่รักษาความมั่นคงทางโครงสร้างที่ดีเยี่ยมตลอดกระบวนการทดสอบการกระจายภาระภายในถูกออกแบบอย่างรอบคอบเพื่อให้ความดัน hydrostatic ได้ถูกโอนไปในระดับเท่าเทียมกันทั่วพื้นผิวกระเป๋า, ลดปริมาณความเครียดในพื้นที่

การเลือกวัสดุที่พัฒนา และความทนทานต่อการสกัด

เปลือกภายนอกของถุงน้ําถูกผลิตจากผ้าเทคนิคที่เคลือบหนักที่มีความแข็งแรงในการดึงสูงและความทนทานต่อการบดการ เลือก วัสดุ แบบ นี้ ทํา ให้ ถุง ใส่ ใส่ ใส่ ใส่ ใส่ ใส่ ได้, พื้นผิวคอนกรีต และสภาพแวดล้อมทะเลโดยไม่เสียสภาพ

การควบคุมภาระที่แม่นยําและประสิทธิภาพในการปฏิบัติงาน

หนึ่งในข้อดีหลักของกระเป๋าน้ําทดสอบภาระ คือความสามารถในการควบคุมภาระที่นําไปใช้ด้วยความแม่นยําสูง โดยการปรับปริมาณน้ําผู้ประกอบการสามารถเพิ่มหรือลดค่าภาระในขั้นเล็ก ๆ, ทําให้สามารถปฏิบัติตามขั้นตอนการทดสอบความจุที่จําเป็นต้องมีการจุเป็นระยะ

การออกแบบที่เน้นความปลอดภัยและการลดค่าใช้จ่าย

ความปลอดภัยเป็นหลักการการออกแบบพื้นฐานของถุงน้ําทดสอบภาระ ถุงน้ําแต่ละถุงมีจุดยกที่เสริมหลายจุดเพื่อให้มีส่วนลดลงระหว่างการแขวนการก่อสร้างเย็บถูกปรับปรุงผ่านการปั่นความถี่สูงหรือการเย็บที่เสริมเสริมเพื่อให้แน่ใจว่าความทนทานต่อการรั่วไหลภายใต้ความดัน.

การใช้งาน

การทดสอบเครนโรงเรือและอุปกรณ์ยก

ในโรงเรือ กระเป๋าน้ําทดสอบภาระถูกใช้อย่างแพร่หลายในการทดสอบภาระของเครนบนหัว, เครน gantry, เครน jib และอุปกรณ์ยกเสริมรูปแบบการขนส่งที่คอมแพคต์และความสามารถในการเติมเต็มในสถานที่ทําให้มันเหมาะสมสําหรับพื้นที่ท่าเรือที่จํากัด.

การตรวจสอบโครงสร้างในทะเลและท่าเรือ

สําหรับแพลตฟอร์มนอกทะเล สถานที่ท่าเรือ และทอร์มิเนลทางทะเล กระเป๋าน้ําทดสอบภาระ ให้คําตอบที่เป็นจริงในการตรวจสอบความจุของและจุดยกโครงสร้างความทนทานต่อการเผชิญหน้ากับน้ําทะเลและสภาพอากาศที่รุนแรง

การทดสอบความจุของโครงสร้างในงานก่อสร้าง

นอกเหนือจากการใช้งานทางทะเล กระเป๋าน้ําเหล่านี้ถูกใช้ในโครงการก่อสร้างเพื่อการทดสอบความหนักของสะพาน ทางเดิน และโครงสร้างชั่วคราวโดยใช้ภาระที่ควบคุมได้ โดยไม่มีการติดตั้งพัสดุบัลลาสต์แบบถาวร, วิศวกรสามารถยืนยันผลการทํางานของโครงสร้างโดยยังคงความยืดหยุ่นของสถานที่.

ทําไมต้องเลือก ฮองรันตอง มารีน

ความเชี่ยวชาญที่ผ่านการพิสูจน์ในทางการแก้ไขการทดสอบภาระทางทะเล

Hongruntong Marine มีประสบการณ์มากมายในการจัดหาอุปกรณ์ทดสอบภาระให้กับโรงเรือนเรือ ท่าเรือ และผู้ประกอบการในทะเลทั่วโลกทีมงานทางเทคนิคของเราเข้าใจความต้องการกฎหมายและการดําเนินงาน ของการทดสอบภาระเรือและอุตสาหกรรม.

การออกแบบและสนับสนุนด้านวิศวกรรมตามสั่ง

เราทราบว่าความต้องการในการทดสอบภาระแตกต่างกันอย่างมากขึ้นอยู่กับประเภทของอุปกรณ์ การทดสอบภาระและสิ่งแวดล้อมการทํางานรวมถึงความสามารถในการบรรทุกที่ปรับแต่ง, การวางแผนการติดตั้งและระบบเชื่อมต่อ

วัสดุที่มีคุณภาพสูง และการควบคุมการผลิต

การควบคุมคุณภาพเป็นหลักของกระบวนการผลิตของเรา กระเป๋าน้ําทดสอบภาระทั้งหมดถูกผลิตโดยใช้วัสดุที่คัดเลือกอย่างรอบคอบ และผ่านการตรวจสอบอย่างเข้มงวด ก่อนการจัดส่งความแข็งแรงของจุดยก, และความแม่นยําของมิติจะถูกตรวจสอบเพื่อให้แน่ใจว่าผลงานคงที่

ขายหลังและเอกสารเทคนิคที่ครบถ้วน

Hongruntong Marine ให้คู่มือผู้ใช้รายละเอียด แนวทางการบํารุงรักษา และใบข้อมูลเทคนิค เพื่อสนับสนุนการใช้สินค้าของเราอย่างปลอดภัยและมีประสิทธิภาพทีมบริการหลังการขายของเราพร้อมตอบคําถามทางการดําเนินงาน, ความต้องการในการเปลี่ยน หรือความต้องการในโครงการในอนาคต

คํา ถาม ที่ ถาม บ่อย

ความจุภาระของถุงน้ําทดสอบภาระมีขนาดไหน?

กระเป๋าน้ําทดสอบภาระ มีให้เลือกในความจุที่หลากหลาย จากหน่วยเล็กที่ออกแบบสําหรับอุปกรณ์ที่มีปริมาณน้ําหนักต่ําไปยังระบบโมดูลขนาดใหญ่ที่สามารถบรรลุภาระความแข็งแรงสูงมากถุงหลายถุงสามารถรวมกันเพื่อบรรลุภาระการทดสอบที่ต้องการในขณะที่ยังคงความยืดหยุ่นในการตั้งค่า.

กระเป๋าน้ําสามารถนําไปใช้ในโครงการต่างๆ ได้หรือไม่

ใช่ กระเป๋าสะพายน้ําถูกออกแบบมาโดยเฉพาะเพื่อการใช้ซ้ํา ด้วยการจัดการ, ตรวจสอบ, และการจัดเก็บที่เหมาะสม มันสามารถใช้ได้ในหลายโครงการโดยไม่สูญเสียผลงานแนะนําให้ตรวจสอบทางสายตาเป็นประจํา และปฏิบัติตามแนวทางการบํารุงรักษา เพื่อให้อายุการใช้งานสูงสุด.

กระเป๋านั้นเหมาะสําหรับสิ่งแวดล้อมในทะเลและทะเลหรือไม่

วัสดุที่ใช้ในกระเป๋าน้ําทดสอบภาระมีความทนต่อน้ําทะเล, การเผชิญหน้ากับแสง UV และสภาพอากาศ ทําให้มันเหมาะสําหรับการใช้งานในทะเลและชายฝั่งการล้างและแห้งที่เหมาะสมหลังจากใช้ในสภาพแวดล้อมทะเลเพิ่มความทนทานมากขึ้น.

การตรวจสอบความแม่นยําของภาระ

ความแม่นยําของภาระถูกบรรลุโดยการควบคุมปริมาณของน้ําที่นําเข้าไปในถุงการใช้เครื่องวัดการไหลของระดับหรือระบบการวัดปริมาตรของปริมาตร ทําให้ผู้ประกอบการสามารถคํานวณภาระที่ใช้ได้อย่างแม่นยํา, รับประกันความสอดคล้องกับความต้องการในการทดสอบความจุ

ความปลอดภัยอะไรที่ควรปฏิบัติตามระหว่างการใช้งาน

ผู้ประกอบการควรให้แน่ใจว่า การเชื่อมต่อการยกทั้งหมดถูกต้องติดตั้ง การเติมเต็มจะดําเนินการอย่างช้า ๆ และพื้นที่ห้ามใช้ในระหว่างการทดสอบการปฏิบัติตามคําแนะนําการใช้งานที่ให้บริการและมาตรฐานความปลอดภัยที่ใช้งานเป็นสิ่งจําเป็นสําหรับการทดสอบภาระที่ปลอดภัยและประสบความสําเร็จ.

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!  ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!